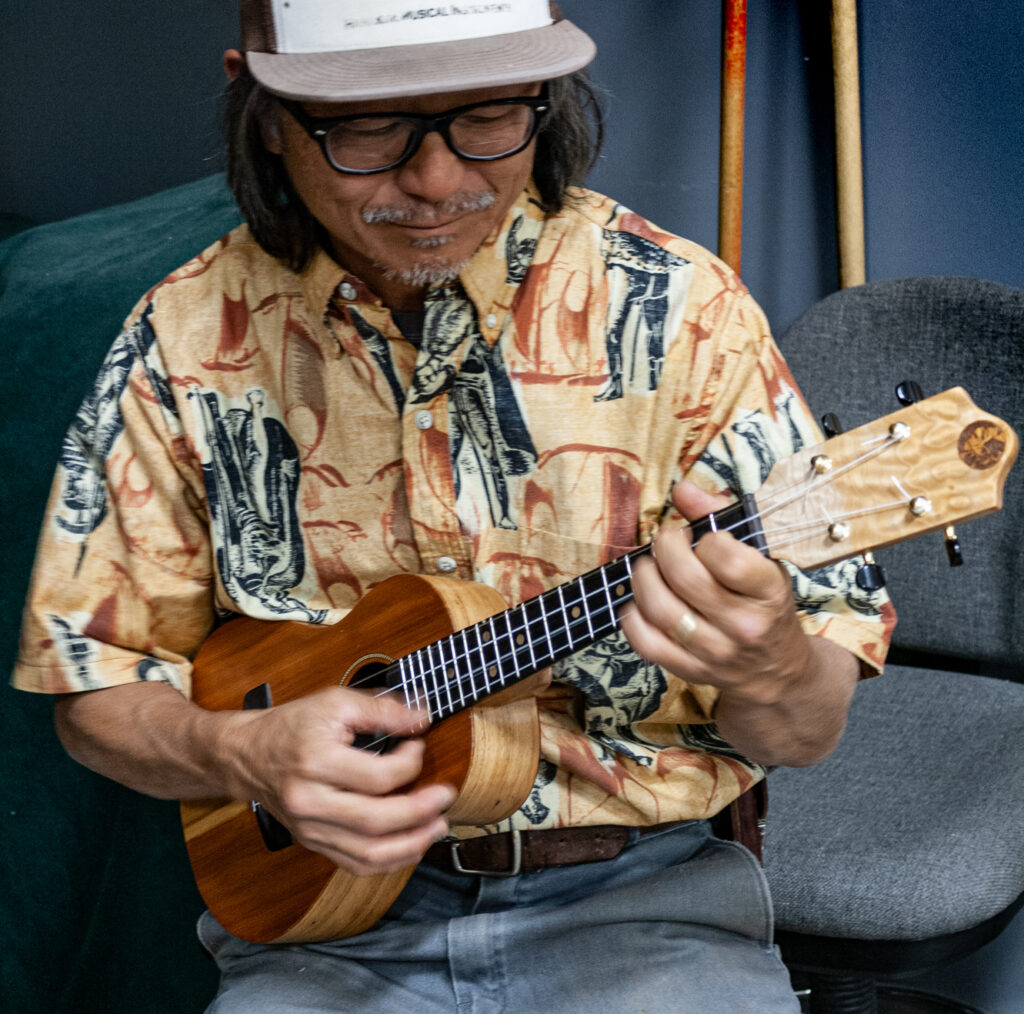

Hāmākua Musical Instruments (HMI) was founded in 2018 by luthier Ross Yamamoto on a small farm in Vista, California. His Hawaiian parents instilled in Ross a love and stewardship for the land and the ocean. From the wood to the glue to the finish, HMI responsibly builds ukuleles by choosing products and processes that have the lightest possible touch on the environment. Our eco-friendly builds exclude the use of tortoise shell, elephant tusk, illegal rainforest woods, and toxic glues or resins. Wood The woods used in our ukuleles are almost exclusively from reclaimed, repurposed, or sustainably grown sources. Some of the woods used to build our ukuleles include: black acacia, cedar, Hawaiian koa, mahogany, redwood, spruce, and sycamore. Our wood sources include:• Reclaimed wood pieces leftover from guitar and surfboard manufacturing.• Hundreds of mahogany species are being sustainably grown and milled in Africa. Fast growing and beautiful in texture and color, it is the backbone of our builds.• Fallen local trees such as Sycamore and Black Acacia have been milled at a community college. We have purchased supplies of this wood with the proceeds going to the college’s school of Cabinetry and Furniture Technology.• Hawaiian Koa trees that have naturally fallen on the Big Island, milled by locals known for their sustainable practices and their respect of Hawaiian culture and customs. Adhesives The glues used to construct our ukuleles are made from fish bones. “Fish glue” is safe, strong, and dries crystal clear. It is non-toxic, non-flammable, and can be cleaned up with water. It can be easily removed for instrument repairs, but will hold strong for the lifetime of a musical instrument. Fish glue is a modern adhesive and is an on par substitute for ancient hide glues, but without the dangers and difficulties of heating and thinning. Many other glues dry so hard that impact damage (like dropping) causes the breaks to form in the wood. Fish glue tends to crack on itself, usually resulting in far less damage than other glues. Adhesive selection in ukulele construction and repair is critical because the wrong one can negatively impact the instrument’s sound quality – as many those doing DIY repairs have discovered the “hard way.” Construction The size and shape of each instrument is chosen to allow the wood to “breathe.” Wood is a natural product. It sometimes has a “will” to resist doing what you want. We try not to fight nature by forcing the wood into a mold. Each instrument will therefore have some measure of its own unique look, size, and shape. Every ukulele will have its own characteristics of sound, feel, and aloha. Finishing Finishes can cause serious environmental and health concerns. Both high VOC and Low VOC paints release pollutants into our atmosphere. Fine instrument building has historically used Shellac. As does HMI. Shellac is made from bug excrement in an alcohol base. It can be polished, dries hard, and can be repaired. Shellac is safe and non-toxic. If you have ever eaten those candies that “melt in your mouth, but not in your hands,” you’ve eaten Shellac. It’s that safe. And it’s what gives the candies (and ukuleles) their shiny coating. Finishing ukuleles with Shellac is a very time-consuming and labor intensive process, but we feel the beautiful results and safety profile merit the effort. We hope you can experience the love and craftsmanship we build into every one of our ukuleles. Feel the Hāmākua. The “breath of the Father” resonating from every single note. Aloha,Hāmākua Musical Instruments